KYAIA

High Speed Shoe Factory

Company overview

Kyaia is the biggest Portuguese footwear group, which constantly invests in state-of-the-art technology,

innovation, image and communication, therefore showing flexibility to new challenges and an entrepreneurial

spirit. The group intends to continue investing in the quality of the service it provides and in the its products

image by developing an innovative design of the own brands, therefore projecting the continuous international

sales increase and keep one step ahead of its competitors. In Portugal, the group has the Fly London’s store

network and the shoe retail chain of Foreva.

Kyaia was founded in 1984, with a productive capacity of 500 pairs of shoes per day and a total of 50

employees. The production was exclusive for exports to the European Union. A year later, it started a close

commercial relationship with Pakistan and doubled the number of its employees. It kept the steady growth

and, in 1987, the production was already of 2000 pairs per day. In 1989, happened the first two relocation

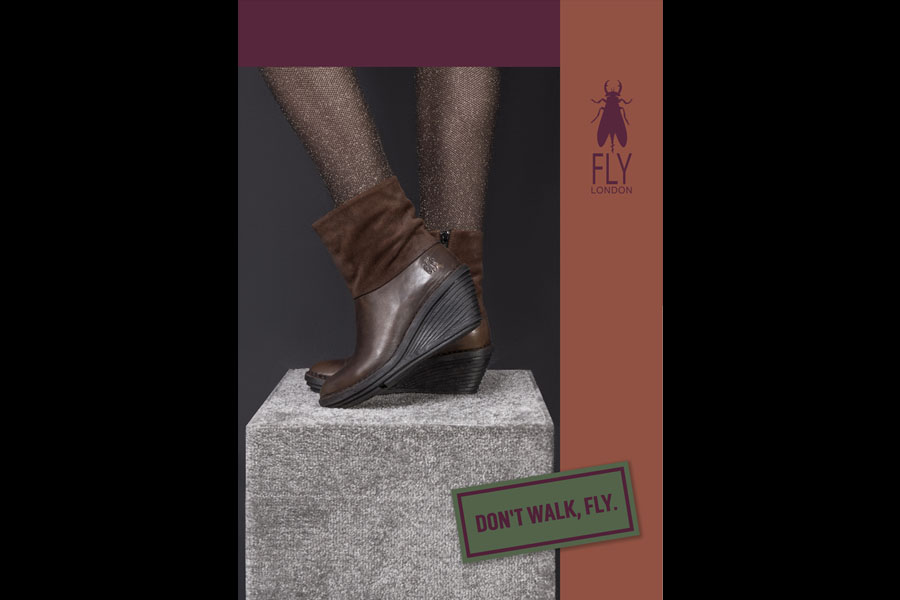

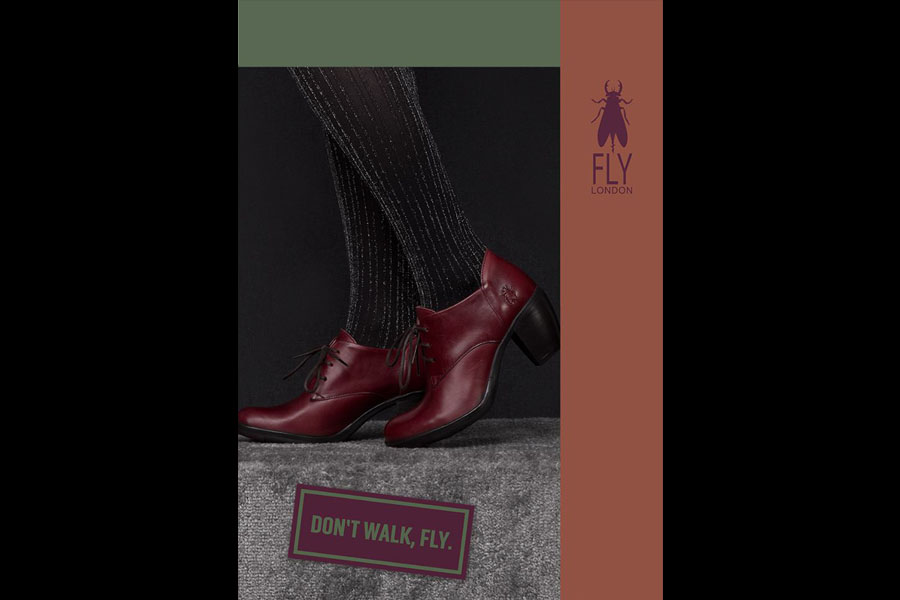

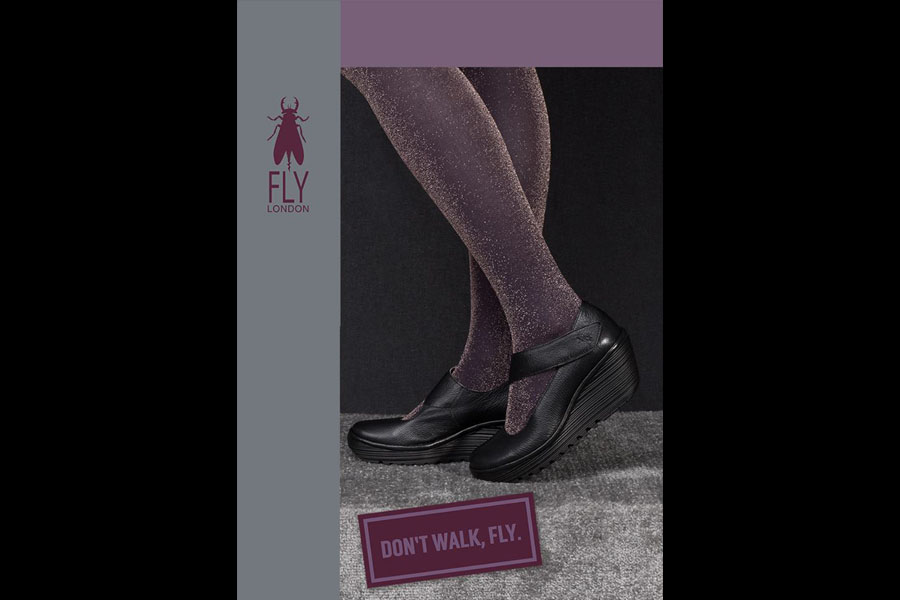

projects, in Pakistan and Paredes de Coura, to manufacture shoe uppers. The own brands FLY London,

Overcube and M.C& Power appeared in 1994.

Company growth

Kyaia’s footwear is currently in 54 countries and the group’s production is of 4500 pairs of shoes per day,

distributing the production between the factory in Guimarães and three other factories in Paredes de Coura,

both in northern Portugal, where the footwear industry has its roots and the vast majority of the Portuguese

footwear is produced.

employees. The production was exclusive for exports to the European Union. A year later, it started a close

commercial relationship with Pakistan and doubled the number of its employees. It kept the steady growth

and, in 1987, the production was already of 2000 pairs per day. In 1989, happened the first two relocation

projects, in Pakistan and Paredes de Coura, to manufacture shoe uppers. The own brands FLY London,

Overcube and M.C& Power appeared in 1994.

Company growth

Kyaia’s footwear is currently in 54 countries and the group’s production is of 4500 pairs of shoes per day,

distributing the production between the factory in Guimarães and three other factories in Paredes de Coura,

both in northern Portugal, where the footwear industry has its roots and the vast majority of the Portuguese

footwear is produced.

In 2014, it announced the ten-year growth plan, in which the goal is to reach, by 2024, a sales amount

of 100 million euros, through a 10 million euros investment in the construction of four new units in

Guimarães. Together with the group’s existing four manufacturing facilities in Paderes de Coura, it will

allow the creation of 300 new jobs.

of 100 million euros, through a 10 million euros investment in the construction of four new units in

Guimarães. Together with the group’s existing four manufacturing facilities in Paderes de Coura, it will

allow the creation of 300 new jobs.

The group will redirect its attentions, with special intensity, to the USA, Canada, New Zealand and

Australia’s markets.

Australia’s markets.

Kyaia seeks to maximize its clients, workers, suppliers and collaborators satisfaction.

The brand Fly London has eight own stores throughout the world and is in 3058 points of sale. Foreva has a

growth strategy based on selected investments that puts the brand in an advantageous position and allows it

to broaden its presence in the main national shopping centers. It has a great geographical coverage with 70

own stores and 25 franchises.

Company research and development

“Ever changing, ever developing” and “Always progressive, never conventional” are the key statements that

inspires everyone associated with the project.

growth strategy based on selected investments that puts the brand in an advantageous position and allows it

to broaden its presence in the main national shopping centers. It has a great geographical coverage with 70

own stores and 25 franchises.

Company research and development

“Ever changing, ever developing” and “Always progressive, never conventional” are the key statements that

inspires everyone associated with the project.

These are the latest technologies develop in IDT innovating projects: HSSF e Shoe ID. This include:

• Integrated products’ moving and transport systems between cutting, sewing, installation, finishing and

packaging sections;

• Management and identification RFID system;

• Management software for sewing automated conveyors with boxes’ storage near the workstations (SmartSL

4.0 - Smart Stiching Logistics);

• 4.0 – Smart Stiching Logistics was a project developed by Kyaia Soluções Informáticas’s engineers in

partnership with INESC TEC, in Oporto, that assures a “agile and flexible management” of sewing lines for the

footwear production. An investment of around 60.000 euros entirely sustained by Kyaia, that is now aiming to

put the software on the market.

• Integrated products’ moving and transport systems between cutting, sewing, installation, finishing and

packaging sections;

• Management and identification RFID system;

• Management software for sewing automated conveyors with boxes’ storage near the workstations (SmartSL

4.0 - Smart Stiching Logistics);

• 4.0 – Smart Stiching Logistics was a project developed by Kyaia Soluções Informáticas’s engineers in

partnership with INESC TEC, in Oporto, that assures a “agile and flexible management” of sewing lines for the

footwear production. An investment of around 60.000 euros entirely sustained by Kyaia, that is now aiming to

put the software on the market.

This solution was tested and implemented in Kyaia’s factory in Paredes de Coura and embodies “advanced

balancing algorithms and production sequencing”, as well as a web interface for an “efficient management” of

sewing and pre-sewing lines, therefore obtaining a better “dynamic affect”. It allows to increase the productive

capacity in 10/15% and reduce the number of employees attached to each and every operation, thus enabling

a higher level of automation.

balancing algorithms and production sequencing”, as well as a web interface for an “efficient management” of

sewing and pre-sewing lines, therefore obtaining a better “dynamic affect”. It allows to increase the productive

capacity in 10/15% and reduce the number of employees attached to each and every operation, thus enabling

a higher level of automation.

Gallery

Company: KYAIA - FORTUNATO O FREDERICO & CA, LDA

Adress: R. 24 de Junho 453, 4800-128 Penselo, Guimarães

Employees: 600 (group) – 344 (company)